Microorganisms play a crucial role in determining the main characteristics of a beer, such as appearance (turbidity, colour), sensation (carbonation), flavour, and aroma, and there is still a world of microbes to be discovered and used in the production of different beers.

Yeasts are the main microorganisms in beer production, with Saccharomyces cerevisiae (ale-type beers) and Saccharomyces pastorianus (lager-type beers) being the most used. Their widespread use is, among other factors, attributed to their high fermentative power – in other words, they are capable of efficiently converting sugars present in the medium into high amounts of ethanol.

In some types of beer, such as sours, bacteria also play a key role in acidifying the drink and giving rise to flavours and aromas not produced (or produced in smaller portions) by yeasts. Currently, microorganisms are recognized as having a great impact on the characteristics of beer, especially in terms of taste and aroma, by producing volatile compounds.

Lambic beers, originated in Belgium, are an example in which the yeast Brettanomyces bruxellensis releases compounds that give the drink aromatic touches described as ‘barnyard’ or ‘horse sweat’, desirable by consumers. Due to their importance in beer production, prospection of new yeasts capable of producing exotic products with commercial value is one of the current research topics in food microbiology with high potential of industrial application. Only recently these unconventional yeasts started to be explored as a way to obtain beers with high quality and sensory complexity, and even low alcohol and caloric contents.

What is beer quality?

There are many aspects to consider as beer quality is measured by a complex set of sensory characters. These indicators are aroma, taste, texture, and appearance.

Together, they defined a sensory profile specific to your brand; this is what makes your beer unique. Preserving this quality at every sip builds your brand loyalty; it keeps your consumers excited about your craft beer.

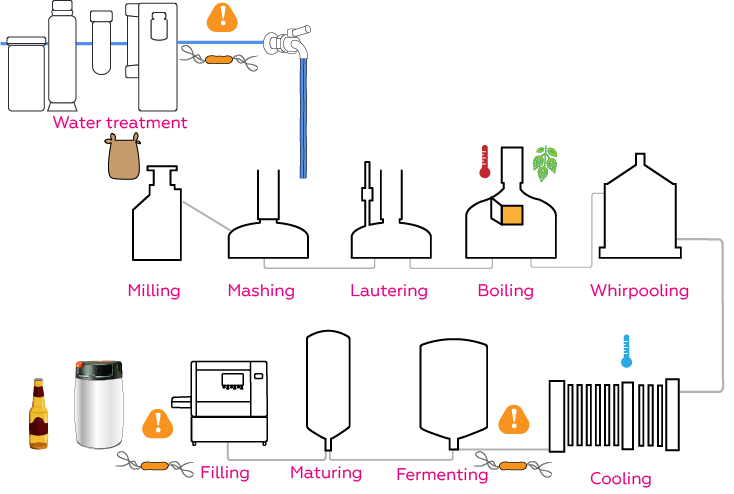

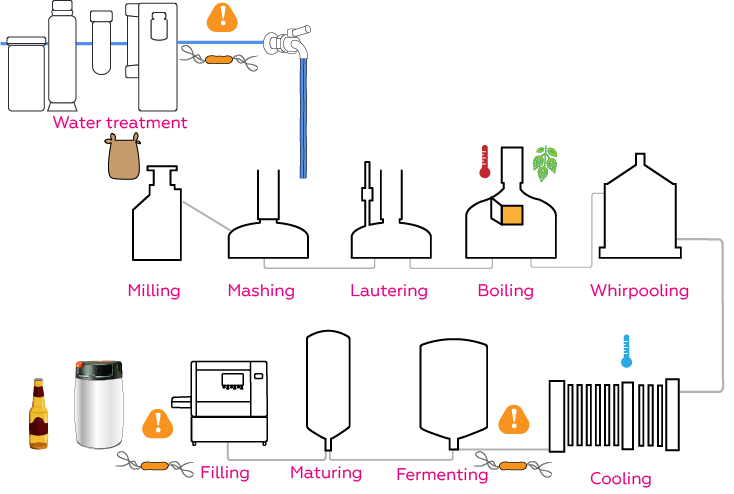

8 Stages where Microbiology Can Impact Beer Taste?

Microorganisms are everywhere, and a brewery working with yeast in a humid environment is the perfect place for microbial contamination. Beer provides nutrients for many undesirable organisms. Where should you start looking for preventing microbial contamination? Microbiological contamination by wild yeasts, molds, and a wide variety of bacterial species can deteriorate the quality of your beer. It can cause off-flavors, souring of beer, over carbonation, the eruption of beer from bottles, and serious hazes

- Barley, Malt, Grits :- In the field, a vast variety of bacteria and fungi are present on the barley. Grinding, grit storage exposes the material to contamination by the environment, stimulated by humidity (condensation) and warmth.

Potential flora: Fusarium, Lactobacillus, ..

Impact: some mycotoxins survive the brewing process and can inhibit yeast growth during brewing, cause premature yeast flocculation, beer gushing/over foaming…

Prevention: store dry and low temperature

- Water :- For brewers, water is indispensable for many things, among which is used as a raw material.

Drinking water contains residual chlorine to prevent bacterial growth in the distribution piping. Treatments to remove scale, unwanted organic matter, and chlorine also removes this protection. Some treatment steps, such as carbon filtration or softeners, can promote the development of microorganisms.

Potential flora: Pseudomonads, Enterobacteria, Cladosporidium,..

Impact: biofilm formation upstream in the process, which contaminates downstream

Prevention: appropriate water treatment system design, techniques and maintenance, short storage, storage at low or high temperature to limit bacterial proliferation

- Lines, fittings, holding tanks :- Anything in contact with the product during the process is susceptible of affecting the product: condensation, incomplete draining, solid material caught on an inner asperity such as couplings can stimulate microbial growth.

Potential flora, from water, brewing material and environment: Lactic-acetic bacteria, enterobaceriaceae, Gluconobacter,..

Impact: production of Acetaldehydes, diacetyl, ..

Prevention : components should be clean, undamaged and sterilized

- Heat exchangers :- The nutrient-rich wort leaving the kettle is vulnerable to spoilage organisms. Heat exchangers are challenging to clean because of their large internal surface and the tortuous channels the wort passes through. The retained organic material in a humid environment is favorable to the proliferation of microorganisms.

Potential flora: Enterobacteria, Lactobacilli, Pediococci, Yeasts

Impact: production of unpleasant flavors, inhibition of Saccharomyces growth

Prevention: proper cleaning and sanitation – rapid fermentation after cooling

- Beer :- Once Saccharomyces and hop are added to the wort, conditions become hostile to most microorganisms. However, when the beer is exposed to environmental contamination, some microorganisms can grow.

Potential flora: Hop-Resistant Lactobacilli, Pediococci, Acetic acid bacteria, Zymomonas (if adjunct sugar)

Impact: acidification, haze, unpleasant aroma

Prevention: Good hygiene practices upstream, limited exposure to the environment and to oxygen

- Bottling equipment :- Bottling is the last process step after which the live microbes escape the brewers’ control. Controlling the sanitary status of that equipment means lowering the risk of undesirable fluctuations in beer stability.

Potential flora: the panoply described above, forming biofilms

Impact: shortened microbial stability

Prevention: proper cleaning and sanitation

- Transportation and storage :- It doesn’t end when your beer leaves your facility! Beer storage areas should be free of food to prevent the growth of microorganisms that could spoil and alter your product.

Potential flora: Pectinatus spp, Megasphaera

Impact: Haze, Off-flavors

Prevention: limit exposure to temperature changes, light and turbulence

- In bars :- When customers ask for your beer at their local bar, they expect the same quality. To ensure a high-quality beer, bar drains should be clean and flushed free of waste beer frequently. It helps prevent microbial growth and fruit flies.

Potential flora : Acetic bacteria, Lactobacilli, Pediococci,..

Impact: Haze, Off-flavors

Prevention: clean faucets, proper serving techniques

Controlling your beer’s quality?

Most of the controls conducted in industrial breweries require a laboratory and some expertise, not always available to small entities. Outsourcing these tests, on the other hand, does not offer the required reactivity and flexibility.

Once a plan of control is established, we believe that every worker in a brewery should be able to control and prevent microbial contamination. That’s why we created Pinqkerton.

Controlling and monitoring microbial activity easily anywhere and at any time could help artisans, managers, and entrepreneurs make high-quality products. With our first product, the “nomad” a self-contained device, you can start monitoring easily and get quantitative results.